Introduction

Problems are inevitable, and everyone faces them in their personal or professional life. When a problem arises, people tend to tackle it with the first available solution without understanding the root cause of the issue. The 5 Whys method is a problem-solving approach that can help you determine the underlying cause of a problem and find a lasting solution. In this blog post, we’ll be discussing what the 5 Whys method is and how it can help you solve any problem.

What is the 5 Whys method?

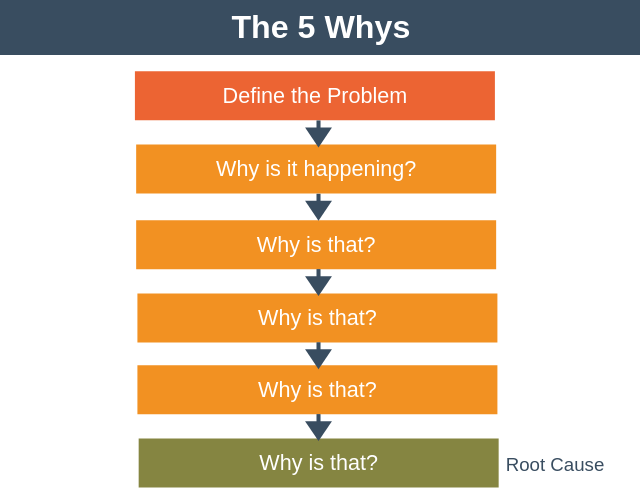

The 5 Whys method is a simple yet effective technique used by many organizations to uncover the root cause of a problem. As the name suggests, you ask “why” five times to get to the bottom of an issue. The questioning process leads you to identify the central problem, and not just its symptoms. The method follows a structured approach, and each subsequent question is based on the previous answer until the root cause is identified.

How to apply the 5 Whys method

To apply the 5 Whys method, you first identify the problem you want to solve and gather a team of people responsible for the issue at hand. Then, you ask why the problem occurred, and the team provides an answer. Based on that answer, you ask another ‘why’ question and continue the process until you uncover the root cause of the problem.

Benefits of using the 5 Whys method

The 5 Whys method offers many benefits, the most significant being the identification of the root cause. By resolving the root cause, you can prevent similar problems from happening in the future. Additionally, by involving a team of people in the questioning process, everyone’s perspective is considered, and collaboration becomes an integral part of problem-solving.

Examples of the 5 Whys method in action

The 5 Whys method is used in various industries, including manufacturing, healthcare, and education. For example, in the healthcare industry, doctors use the 5 Whys method to determine the root cause of a patient’s symptoms. The technique helps doctors to identify whether the symptoms are due to an underlying health issue or side effects of medication. In the manufacturing industry, the 5 Whys method is used to identify the cause of equipment breakdowns, which helps prevent unplanned downtime.

Tips for successful implementation of the 5 Whys method

To get the most out of the 5 Whys method, it’s essential to involve a cross-functional team with different perspectives. Additionally, take the time to understand the problem, and ask open-ended questions to get to the root cause. Lastly, track your progress and results as you implement solutions based on the 5 Whys method.

Conclusion:

In conclusion, the 5 Whys method is an effective problem-solving technique that can be used in any industry or situation. By asking why five times, you can identify the underlying cause of a problem and implement a lasting solution. Remember to involve a team of people, ask open-ended questions, and track your progress to get the most out of this method. The 5 Whys method is simple, yet powerful, and it can help you solve any problem.